Inventory Management System

Introduction

Managing complex inventories of high-value components is a challenge faced by many scientific and industrial facilities. The Inventory Management System (IMS) is a web-based platform designed to streamline the tracking, organisation, and lifecycle management of thousands of items such as optics, electronics, and mechanical parts.

The Problem

Modern research facilities rely on complex infrastructures where downtime can be costly and disruptive. Traditional inventory tracking methods such as spreadsheets and static documents struggle to scale with growing operational complexity. As facilities expand, the need for a centralised, dynamic, and scalable inventory solution becomes critical to ensure efficiency and reduce downtime.

Our Solution

IMS offers a centralised web-based platform for managing inventory across complex infrastructures. It can categorise different parts, create individual records for physical entities and move these records between systems, tracking their usage condition. IMS also keeps track of spares, so you will always know when the best time to order new parts is. IMS enhances availability, supports forecasting, reduces operational costs, and minimises downtime. The system is continuously evolving, with new features and improvements being released based on user feedback and operational needs.

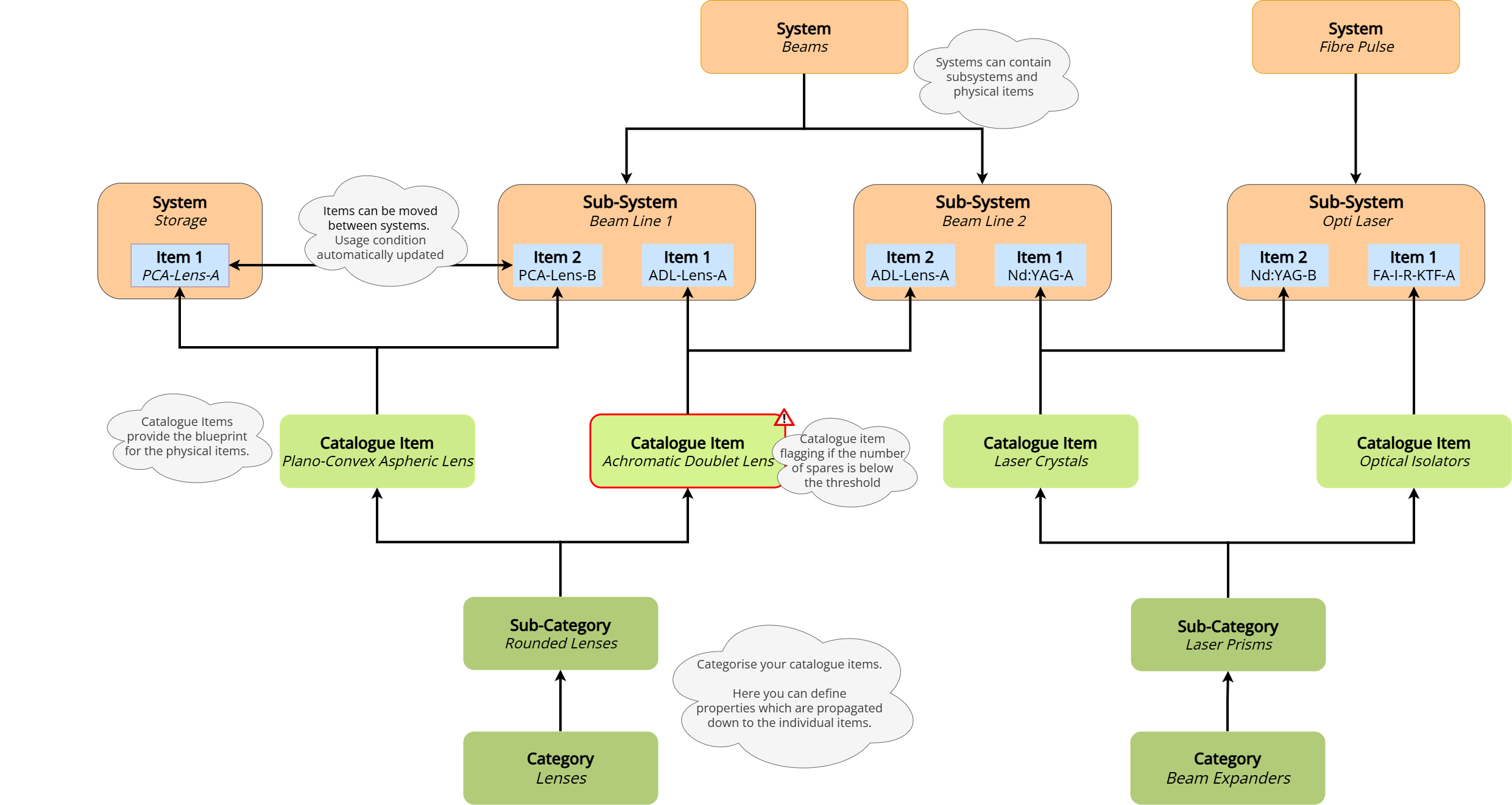

Below is an example use case of IMS for a Scientific Research Facility:

IMS structure overview: Detailed categorisation, for catalogue items and systems. Items which can move dynamically between systems. Our solution provides a comprhensive overview of your inventory.

IMS structure overview: Detailed categorisation, for catalogue items and systems. Items which can move dynamically between systems. Our solution provides a comprhensive overview of your inventory.Applications

How can IMS apply to you

Transportation & Logistics - Manage parts for vehicles, equipment, and infrastructure across depots and distribution hubs.

Manufacturing - Manage machine components, tooling, and maintenance-critical parts across production lines.

Healthcare - Manage parts for equipment used at healthcare facilities.

Research Facilities - Manage specialised parts for instruments, laboratories, and experimental infrastructure.

Quick Glance

Below are several key interfaces that highlight the functionality and design of the system:

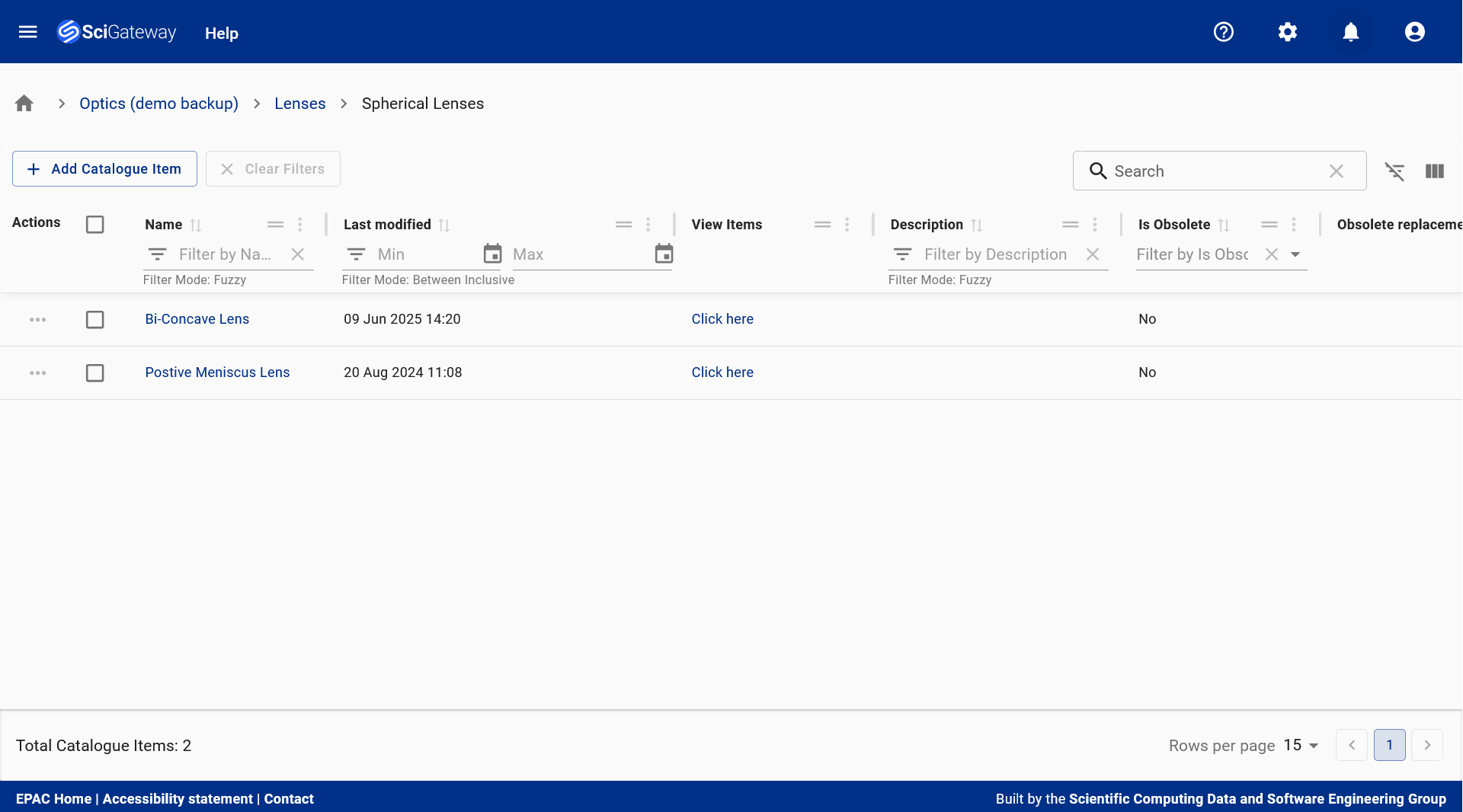

Catalogue Items Table: Displays structured commercial representations of physical items, including names, descriptions, lifecycle status, and procurement details - supporting efficient planning, quoting, and inventory management. Here you can also view the number of spare items, a key indicator for when to purchase more inventory.

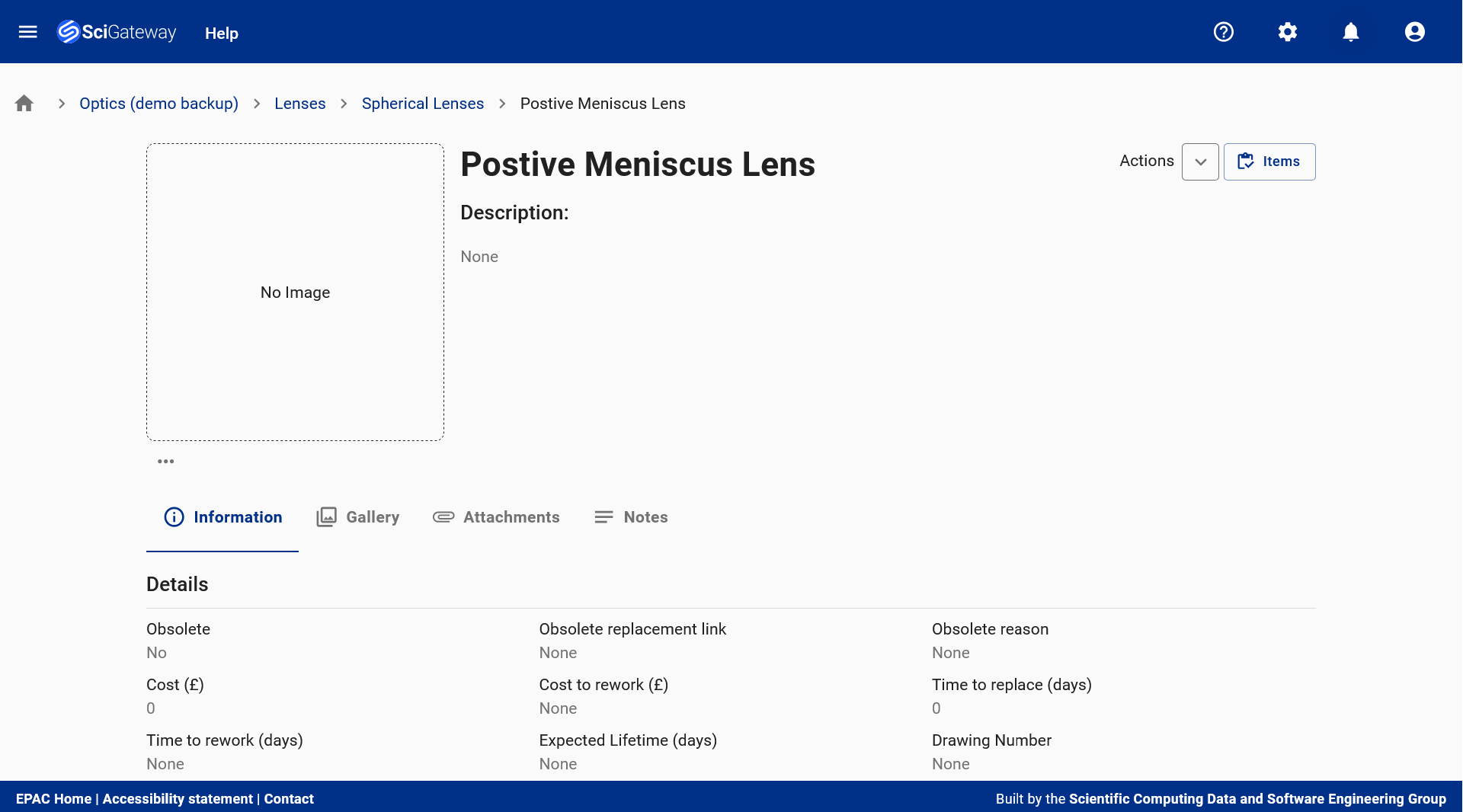

Catalogue Items Table: Displays structured commercial representations of physical items, including names, descriptions, lifecycle status, and procurement details - supporting efficient planning, quoting, and inventory management. Here you can also view the number of spare items, a key indicator for when to purchase more inventory. Catalogue Item Landing Page: Provides a centralised view of a catalogue item, combining technical specifications, metadata, gallery, attachments, and notes to support procurement, documentation, and lifecycle tracking.

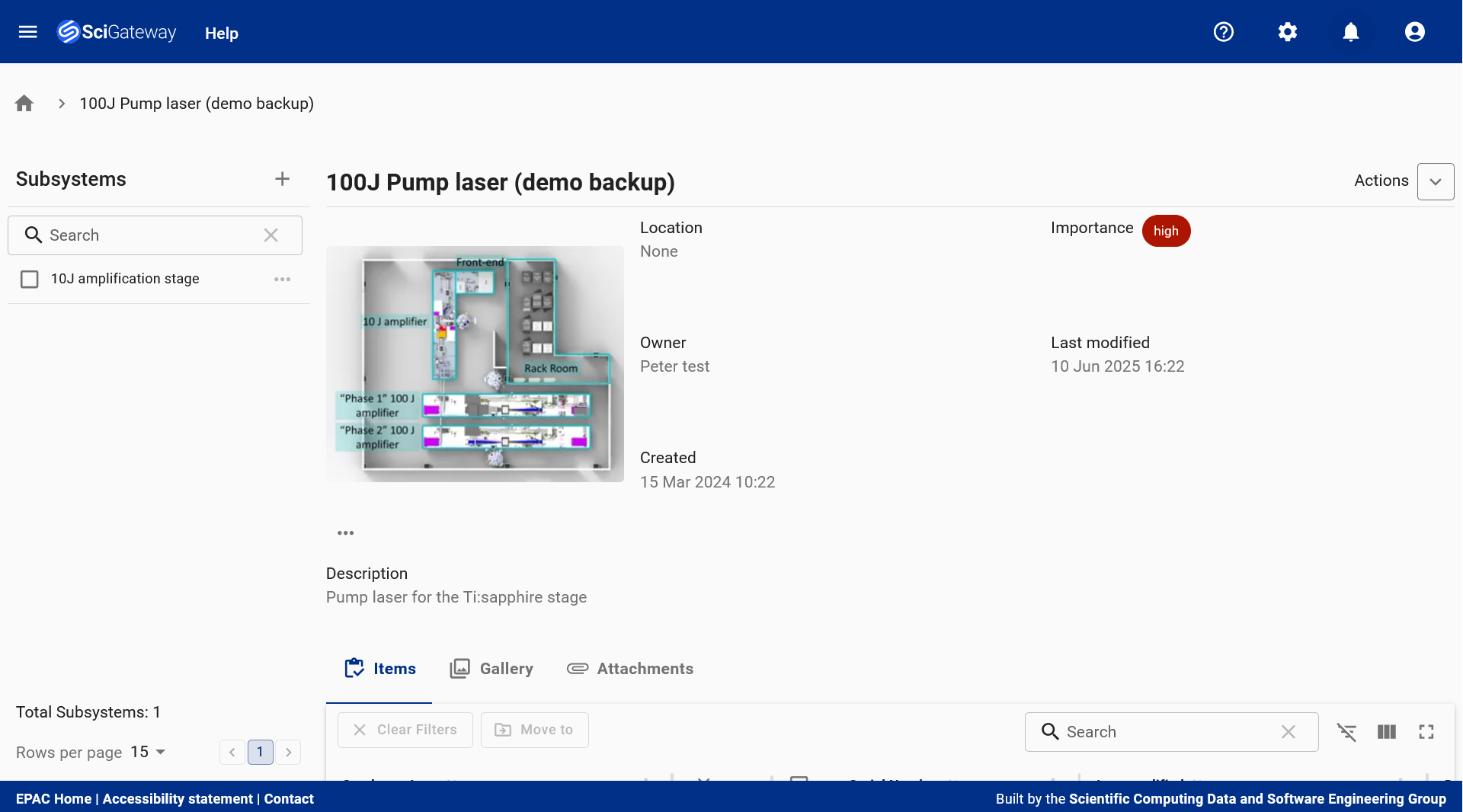

Catalogue Item Landing Page: Provides a centralised view of a catalogue item, combining technical specifications, metadata, gallery, attachments, and notes to support procurement, documentation, and lifecycle tracking. Subsystem Dashboard: Offers a comprehensive view of the '100J Pump Laser (Demo Backup)' subsystem, displaying its type, associated items, metadata, images, and attachments to support high-priority component tracking and lifecycle management.

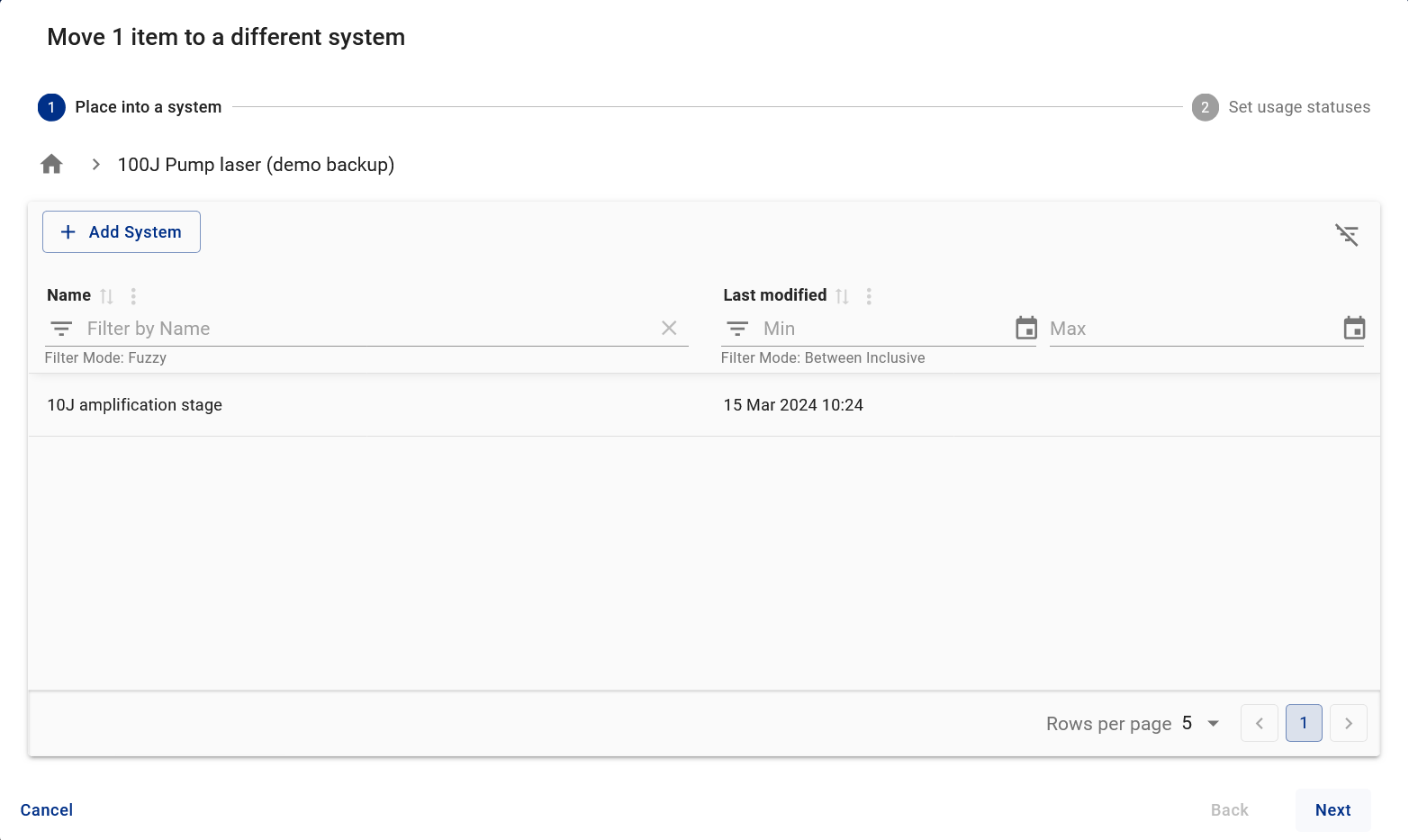

Subsystem Dashboard: Offers a comprehensive view of the '100J Pump Laser (Demo Backup)' subsystem, displaying its type, associated items, metadata, images, and attachments to support high-priority component tracking and lifecycle management. Moving Items: The 'Move To' Dialog facilitates the transfer of physical items from storage into the '100J Pump Laser (Demo Backup)' subsystem - ensuring accurate tracking and seamless integration within the system hierarchy. Movement of items between systems is restricted based on rules.

Moving Items: The 'Move To' Dialog facilitates the transfer of physical items from storage into the '100J Pump Laser (Demo Backup)' subsystem - ensuring accurate tracking and seamless integration within the system hierarchy. Movement of items between systems is restricted based on rules.Contact Us

Please email the development team at ims-support@stfc365.onmicrosoft.com for any enquiries.